Installation instructions for digital ignition Kundo PVL

Only suitable for racing, with no light generator

| KRD-Nr. IG 301.00 | suitable for Minarelli Engines: |

| Aprilia | Amico, Scarabeo, SR Replica, Rally 50 |

| Beta | Crono, Quadra 50 |

| Italjet | Pista, Scoop 50 |

| Malaguti | F-10, F-12 |

| MBK | Booster, Booster NG 50 |

| Rieju | Windy, First 507F10 |

| Yamaha | BW’s-50-65, Spy, Jog, Jog R, Axis, Zest 50 |

Digital ignition with internal rotor (not programmable)

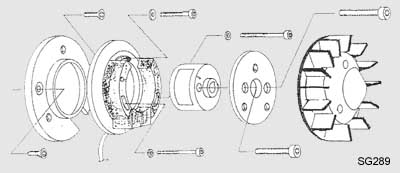

The electronic ignition system KRD with internal rotor, designed exclusively for use in bicycles / scooters includes the holders of the stator coil group and the fan wheel, and all fasteners (adapter plates).

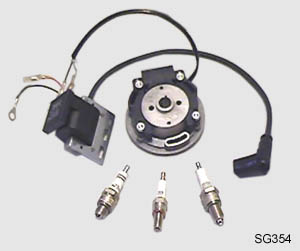

The ignition system consists of the following parts:

- Stator No. 1007

- Rotor No. 9905

- Coil No. 466 101

- CDI-Unit No. 464 228

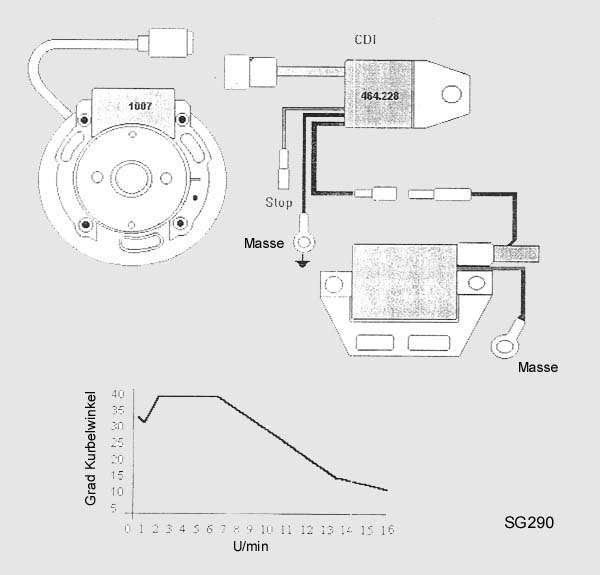

For this, the ignition curve is the image SG290

Technical Note

This product improves the performance of every two-stroke engine (from 50 cc to 125 cc), since its ignition curve has determined that an optimum performance is achieved. This was confirmed in experiments on the test bench. The ignition timing can be adjusted by rotating the base plate. The base plate is screwed onto the engine casing by three slots (or the adapter plate) screwed. See detailed Installation instructions.

The crankshaft keyway is invalid! The cone of the crankshaft and the inner cone of the rotor, prior to installing the rotor should be cleaned with acetone. Fix the Stator properly on the motor housing or the mount on to the adapter plate. First, set the middle position of the stator slots. For adjustment of the ignition timing use either a graduated disc or a micrometer. We recommend micron KRD No. HT12.00 + Nr.HT20.00/HT21.00. The engine shall be turned first by hand to TDC. The black line on the stator and the raised line on the rotor should correspond. The ignition timing should be set to 6 mm before TDC or 37 ° crank angle. Regardless of which method you use, the stator must be brought in by rotating the position that the two marks correspond at either 6 mm before TDC or 37 ° crank angle. For this purpose, it may be necessary that the process is adjusted several times until an optimal result is achieved. If the setting values are ??correct, the screws can be tightened to the manufacturer’s specified torque.

KRD, Kundo, F Murcia SA assumes no liability for damages incurred due to incorrect installation

The parts with the following numbers have the same ignition curve

| Nr. 105 500 54 | Ignition Coil |

| Nr. 105 500 97 | Ignition Coil |

| Nr. 500 104 | Ignition Coil |

| Nr. 464 228 | CDI |